MORE FREE TERM PAPERS MANAGEMENT:

|

|||||||||||||||||||||||||

OPERATION MANAGEMENT - Bata

BRIEF HISTORY OF THE BATA COMPANY

The

business that became the Bata Shoe Organization was established on August

24, 1894 in Zlin, Czechoslovakia by Tomas Bata, and included

his brother Antonin and sister Anna. Although this business

was new, the Bata name had been part of a tradition of shoemaking for

eight generations, spanning three hundred years.

The

business that became the Bata Shoe Organization was established on August

24, 1894 in Zlin, Czechoslovakia by Tomas Bata, and included

his brother Antonin and sister Anna. Although this business

was new, the Bata name had been part of a tradition of shoemaking for

eight generations, spanning three hundred years.

It was one of the first modern day shoe ‘manufacturers’ , a team of snitchers

and shoemakers creating footwear not just for the local town , but also

for the distant retail merchants. This departure from the centuries old

tradition of the one man cobbler’s workshop was a brand new concept, creating

an entirely new industry.

The Bata enterprise revolutionized the treatment of employees and labor

conditions. Tomas consistently maintained a human focus, creating opportunities

for development and advancement, and added compensation for employees

based on achievement.

In late 1985. Antonin was drafted into the army for compulsory military

service and lift family shoe business. Also that year, Anna left the company

to marry, leaving a young Tomas to build the business on his own.

By 1905 Tomas had taken the new enterprise to 2200 pairs of shoes per

day , produced by 250 employees – utilizing resourceful imaginations ,

skilled hands and modern machinery to keep up with demand. Under this

‘manufacturing’ system, productivity was greater than even before.

Bata shoes were excellent quality and available in more styles than had

been offered before. Demand grew rapidly in the early 1900s. Despite material

and manpower shortages, cartel and the outbreak of World War 1, sales

continued to increase, reaching two million pairs per year by 1917.

As the enterprise prospered, so did the communities where it operated,

Tomas believed that a focus on people and public service was critical

for business success. The enterprise built housing, schools and a hospital

near the shoemaking plant in Zlin. It provided food and inexpensive rent

during very difficult times; when there was no help to be found. Bata

companies alter provided rail services, construction, insurance, publishing

and tannery in Zlin.

Following World War 1, consumer purchasing power was very low; Tomas and

his employees devised a plan to adjust to post-war economic difficulties

and reduced their shoe prices. Bata stores were flooded with buyers and

industry cynics were forced to follow their lead.

Already exporting to other European countries, Northern Africa and the

USA, the enterprise began establishing new sales organizations in these

markets during the 1920s. Companies were opened in Poland, Yugoslavia,

Holland, Denmark, United Kingdom and the USA. By the early 1930s, the

Bata enterprise and Czechoslovakia were the world’s leading footwear exporters.

“The Bata System” devised by the Zlin team, and later applied in other

Bata Show Organization companies, organized operations into autonomous

workshops and departments, allowing employees to contribute ideas and

stimulate production, and contributed significant breakthroughs in footwear

technology.

BATA INDIA

Bata India Limited

Incorporated as Bata Shoe Company Private Limited in 1931, the company was set up initially as a small operation in Konnagar (near Calcutta) in1932. In January 1934, the foundation stone for the first building of Bata's operation - now called the Bata. In the years that followed, the overall site was doubled in area. This township is popularly known as Batanagar. It was also the first manufacturing facility in the Indian shoe industry to receive the ISO: 9001 certification.The Company went public in 1973 when it changed its name to BataIndia Limited. Today, Bata India has established itself as India's largest footwear retailer. Its retail network of 1250 stores gives it a reach/ coverage that no other footwear company can match. Thestores are present in good locations and can be found in all the metros, mini-metros and towns Bata's smart looking new stores supported by a range of better quality products are aimed at offering a superior shopping experience to its customers. And the new face of Bata India is now visible to the industry as well as its customers. Today, backed by a brand perception of experience, the company is working towards positioning itself as a vibrant and contemporary young brand. It has significantly transformed its retail formats to become more lifestyle-oriented, which has helped change consumer perceptions to a large extent.

Bata India - Today

•Sells over 45 million pairs of footwear every year

•Serves over 120,000 customers every day

•Sells through over 1200 retail stores

•Operates 5 manufacturing facilities

•Employs more than 6800 people

BATA’S BUSINESS UNITS

- Bata Europe, Lausanne

- Bata Asia Pacific-Africa, Singapore

- Bata Latin America, Mexico

- Bata North America, Toronto

Bata is one of the world leading footwear retailer and manufacturer with operations across 5 continents managed by 4 regional meaningful business units (MBUs). The MBU approach provides quality resources and support in key areas to the companies operating in similar markets such as product development, sourcing or marketing support. Each MBU is entrepreneurial in nature, and can quickly adapt to changes in the market place and seize potential growth opportunities.

Bata's strength lies in its worldwide presence. While local companies are self-governing, each one benefits from its link to the international organization for back-office systems, product innovations and sourcing.

Although Bata operates in a wide variety of markets, climates and buying power Bata companies share the same leadership points. Two important ones are product concept development and constant improvement of business processes in order to offer customers great value and the best possible service.

VISION

To grow as a dynamic, innovative and market driven domestic manufacturer

and distributor, with footwear as our core business, while maintaining

a commitment to the country, culture and environment in which we operate

MISSION

To be successful as the most dynamic, flexible and market responsive organization,

with footwear as its core business

BATA BUSINESS

Bata shoe Organization companies are involved in every face of the business

of shoes. Throughout the world, Bata companies service customers from

the store sales floor to the factory floor.

PRODUCT RANGE

Marie Claire

- Hush Puppies

- Power

- Bubble Gummers

- North Star

- Scholl

- Weinbrenner

Product range starts of Bata 299-2499. Bata start range 299 to lowest

range of school shoe and highest brands of power & other product.

Bata product lowest to highest range available to market.

Hush Puppies – Now in India

Hush Puppies are a famous shoe brand of the USA. It is so famous and pioneering

that it’s sometimes referred to as a legend. This brand is owned and operated

as a division by the Wolverine...

Bata is worst shoe maker

Bata is the people who make shoes for high prices but with low quality.

i bought a pair of slippers from bata named "comfit" for Rs.

749/- on may 2007. it is not compfortable at all. The slipper is made...

Poor quality shoes

I bought one pair of leather shoes from Bata, Cochin dealer near Padma

junction one year before. The product was formal shoes with laces. The

shoes cost INR 1499 for me.

High Price Poorest Quality

I just happened to buy Bata shoes a week back. The item I bought was obviously

overpriced, but going by the name bata I bought it at 499. Within a weeks’

usage, the shoe sole was partially ripped off!

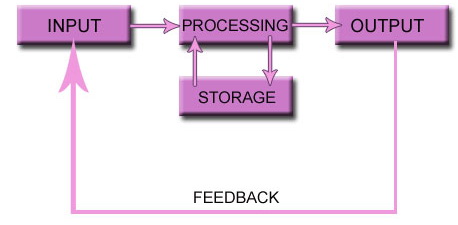

TRANSFORMATIONAL PROCESS VIZ INPUTS OUTPUTS AND PROCESS FOLLOWED IN CONVERSION

In order to handle the increasing complexity of distributed industrial

manufacturing systems, there is a strong demand for methods and tools

that support the designer in the analysis and optimisation of flexible

infrastructures for the automation of production processes. We are currently

investigating how emerging standards and advanced simulation techniques

can be exploited successfully in the production of custom made shoes.

Nowadays, many different approaches, methodologies and computer aided

design tools can be employed in the analysis and optimization of complex

industrial systems. As a consequence, the selection of the most appropriate

techniques and tools for a particular system is critical. Before making

any final decision, it is necessary to investigate the functionalities

offered, compliancy with existing standards, and capacity for interoperability

with non-proprietary instruments. We are currently working on a methodological

approach to the structured design and simulation-based analysis and optimisation

of manufacturing plants. The methods and tools used during the different

phases of the design are illustrated with reference to an application

in the shoe manufacturing sector. In particular, we describe an innovative

plant for the production of customized shoes. This plant is located at

the ITIA-CNR laboratory in Vigevano (Italy) and constitutes the pilot

plant of a large European research project called EUROShoe, which began

in March 2001 and is scheduled to finish in June 2004.

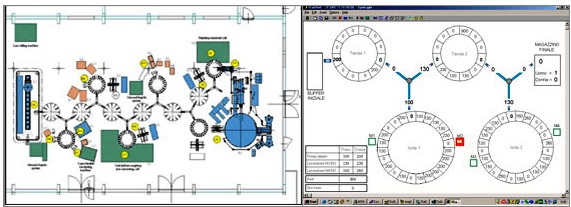

Figure 1: The Innovative Shoe Manufacturing Plant

EURO Shoe is a complex and ambitious project with thirty-five academic

and industrial partners from ten different European countries. It aims

at a dramatic renovation of the concept of shoes as products and of their

production, based on a transformation from mass-produced to mass-customised

goods. This product evolution goes in parallel with a transformation of

footwear companies into distributed and flexible enterprises capable of

handling the complexity that such a radical change in the nature of the

product implies and of mastering the associated new technological challenges.

This implies a complete revision not only of the entire manufacturing

process but also of the tools used to analyse and optimize the resulting

innovative industrial system.

For the sake of brevity, the methods and tools used for the design, analysis

and optimization of the plant automation system are outlined with reference

to the control and supervision of the transport line. In the shoe manufacturing

plant that we consider (Figure 1), an innovative transport line is used

to move the semi-finished shoes from one machining station to another

according to a predefined operating schedule. In particular, the innovative

molecular structure of the transport line (Figure 2) strongly enhances

the modularity, scalability, integrability and reconfigurability of the

production system, thus increasing the overall flexibility of the plant.

Figure 2: Layout of the Shoe Plant (left) and ISaGRAF Simulation Graphical

Interface (right).

At the beginning of the design life cycle, the control and supervision

system of the transport line was specified by means of UML (Unified

Modelling Language) diagrams; in particular use-case, class, sequence

and state diagrams were used to specify the systems modules, their relationships

and their dynamic behaviour. The system architecture and functions were

designed using the Function Block formalism defined by the IEC 61499 standard,

which integrates object-oriented concepts and discrete event models to

suitably support control software design. The functional model obtained

was analysed and optimized by means of closed-loop discrete event simulations

performed in the Simulink/Stateflow environment, where both the controller

and the controlled process were modeled and simulated through state charts,

as was the behaviour of the overall system. In this way, the correctness

and performance of the solution proposed could be evaluated. In particular,

a bottom up methodology was defined and exploited to study the system

according to a modular approach. This enabled us to simplify the overall

analysis process, to verify the correctness of the automation functionalities

easily and to optimize the system performance from the very first phases

of the design life cycle. Once the functional modules had been verified,

the control and supervision algorithms were developed using the SFC (Sequential

Functional Chart) formalism, which is an advanced discrete event

modelling graphical language, directly derived from Petri nets, and included

in the IEC 61131 part 3 standard, which defines programming languages

for industrial PLCs (Programmable Logic Controllers). The SFC

algorithms were analysed through closed loop discrete simulations in the

ISaGRAF environment in order to verify their correctness and to optimize

their performance. ISaGRAF is a CACSD (Computer Aided Control System

Design) tool that allows the automation software to be structured

using all five IEC 61131 languages and supports simulation functionalities

for testing purposes, as well as automatic code generation facilities

for different industrial systems. In order to perform the closed loop

simulations, simplified models of the plant devices have been represented

in ISaGRAF by means of suitable SFC modules and data structures. Moreover,

to simplify the analysis of the simulation results, a simple 2D graphic

animation was realized in ISaGRAF (Figure 2). Simulations have been performed

by considering typical operating conditions, ie, typical production orders,

and the results obtained show that the system is deadlock free and that

the plant is well balanced, ie its resources are all used effectively.

After verification and optimization of the automation functions and algorithms,

the corresponding code was generated and implemented on the target industrial

devices. We found that the simulation-based analysis techniques reduced

the plant rump-up times and costs and improved overall system performance.

Future work will concern the exploitation of the standards, methods and

tools proposed for other industrial plants and their integration within

an advanced CACSD tool for manufacturing systems

MANUFACTURING

Tomas Bata’s revolutionary business concept was to industrialize the shoemaking

process of that day. That type of thinking has been the driving force

behind the Bata Shoe Organization success.

The Bata Shoe Organization has been as innovator in the manufacturing

of shoes over the years. Bata personnel have made important advances in

DVP (Direct Vulcanization Process), PVC, athletic footwear production

and slush – molded footwear production.

1. Raw Material Stock

The raw material which includes the chemicals used for making cement adhesive,rubber

latex and sole (both inner and outer),cloth(bought from Bombay Dyeing)

used for making upper, material used for making binding,thread and the

packing cartons etc. are stocked in the warehouse. Inventory of all the

above items is properly maintained with the help of a ‘Material stock

position’ chart made on the walls of the warehouse and a computerized

inventory Database.

Every department has been allocated a maximum stock limit beyond which

they cannot store the raw materials for themselves. It has to be used

as frequently as possible. Every fortnight, the stock and usage is reviewed.

The transmission of raw material from stock warehouse to respective departments

is recorded and same is done with the transmission between various departments.

All this data is readily available for review to all departments and can

be checked anytime.

Cement And Latex Manufacturing:

The cement adhesive and rubber latex are the main chemicals used to paste

together the different part of a shoe, are manufactured in the plant itself.

Both these materials are produced keeping in mind the exact requirements

and also the correct specification, which is the right mix of chemicals

to make it the best pasting element and get the desired quality.

1. Sole Pull Manufacturing:

The inner and outer shoe required in the shoe are also produced in-house.

Huge rubber sheets measuring 3ft.x2ft. having a thickness of approx. 2

cms. are first heated to high temperature and then placed in a curing

chamber for 8 minutes where they are again processed at high temperature

of around 170oC. At such a high temperature the sheets expand and then

sent for vulcanization where it is processed for 3 hrs. to set the shrinking

limit of rubber. These sheets can be cut only after two weeks of vulcanization.

This is known as seating process.

2. Making Binding:

A binding is required on the outer of the shoe to bind the edges of cloth

upper. This binding material is also made within the plant, using cloth.

It is machne stitched onto the cloth upper.

3. Folding, Cutting And Stamping:

The cloth that forms the shoe upper is produced from Bombay Dyeing. It

is first folded into huge lots and then cut into pieces of uniform sizes

according to the different size lots.These cloth pieces are then stamped

with what may be called a batch number and the shoe size. An example of

a batch number may be “F-3218422”. In this code, F represents plant code

of the Faridabad factory, 321 is the code of the particular workstation

and assembly line, 8 represents the year of manufacturing, 42 the week

and 2 signifies the day of the week in which production has been done.This

stamping particularly helps if there is a defect found out in the shoe

after sale. After stamping is done ,the upper is sent for stitiching.

4. Stitching :

The cloth received after stamping is set for stitching and making it into

a proper upper of the shoe. The stitching process starts with folding

of the piece and stitching it in a particular fashion to give the shape

of an upper. Next, it is sent for stitching the binding onto the edges

of the sgoe. After the binding on the edges has been done, the shoe is

transferred further where lace holes and flips used under that are stitched

onto the upper. The last step in the stitching process is to put laces

into the shoe, which is done by hands. The upper of the shoe is now ready

to sent for assembling process.

5. Assembly:

The assembly process uses a dual level conveyor belt as can be seen in

the picture.

A fact worth noting is that the conveyer does not have a linear arrangement

of workstations; rather it is an ellipsoidal conveyer with different workstations

positioned all around it. At first glance, it is not easy to comprehend

as to wherefrom where the process begins. However ,a closer look reveals

that fully assembled shoes are hand picked away from the conveyer at one

particular point on the conveyer. Despite it unconventional designe, it

is a very well organized and systematic assembly line configuration where

none of the employee sit idle at any point of time , thus minimizing idle

time losses.

There is a parallel conveyer which basically consists of many metal shoe

moulds onto which the entire shoe assembly is built.

The shoe building process starts at one when one person applies cement

on the inner sole and places it on the conveyer belt. The next person

then applies cement of edges of the upper of the shoe and again puts back

the piece onto the conveyer, next,the inner sole is put on the upper part

of the

Mould and the cloth is pasted on the sole to get the exact shape of the

shoe. Now ,when the shape is achieved ,the shoe is dipped into latex so

that the latex covers the lower side of the shoe.

It is then placed in a drying chamber to dry the latex where in the temperature

is around 70 C.

Once latex is dried and the shoe is taken out of chamber . It is again

placed on the conveyor and the next person puts the outer sole(coated

with cement) on the conveyor as well. The sole is then pasted on to the

shoe tightly and pressed by a large bag containing water. This water filled

bag is a part of the conveyor only and water is used to prevent the formation

of air bubbles, which may leads to manufacturing defects.

The person sitting next checks once again that there is no gap in the

pasting. The side fixing is then pasted on the dried latex and the shoe

moves on. The next employee pastes the Bata logo on the back of the shoe

and also press the side foxing. On the next station, the toe guards, both

side strips as well as circular one, are available to the employee.

Coated with cement . Both of these are pasted on the shoe. The shoe is

now prepared to be vulcanized and hence is transferred by the last worker

on the conveyor , from the conveyor to the conveyor trolly.

BIBLOGRAPHY

http://www. Bata.com

www.product range.com

http://www.bata manufacturing process.

www.consumercomplaints.in/