MORE FREE TERM PAPERS MANAGEMENT:

|

|||||||||||||||||||||||||

Enterprise Resource Planning (ERP) system

Implementation-Procedures, Issues, Challenges & Failures

An Enterprise Resource Planning (ERP) system is an integrated computer-based application used to manage internal and external resources, including tangible assets, financial resources, materials, and human resources. Its purpose is to facilitate the flow of information between all business functions inside the boundaries of the organization and manage the connections to outside stakeholders. Built on a centralized database and normally utilizing a common computing platform, ERP systems consolidate all business operations into a uniform and enterprise-wide system environment.

An ERP system can either reside on a centralized server or be distributed across modular hardware and software units that provide "services" and communicate on a local area network. The distributed design allows a business to assemble modules from different vendors without the need for the placement of multiple copies of complex and expensive computer systems in areas which will not use their full capacity.

To be considered an ERP system, a software package should have the following traits:

- Should be integrated and operate in real time with no periodic batch updates.

- All applications should access one database to prevent redundant data and multiple data definitions.

- All modules should have the same look and feel.

- Users should be able to access any information in the system without needing integration work on the part of the IS department.

Various modules of ERP System are:

- Transactional Backbone

• Financials

• Distribution

• Human Resources

• Product lifecycle management

- Advanced Applications

• Customer Relationship Management (CRM)

• Supply chain management software

- Purchasing

- Manufacturing

- Distribution

• Warehouse Management System

- Management Portal/Dashboard

• Decision Support System

These modules can exist in a system or can be utilized in an ad-hoc fashion.

Prior research has shown that conflict with consultants is one of the main managerial problems during the implementation period of ERP system (Themistocleous et al., 2001). Consultants can bring to the organisation specialised skills, experience, and know-how that the organisation needs when it is both time-consuming and expensive for it to build internally (Gable, 2003). They can also offer a firm-wide view, encourage unity between members, and they are usually neutral (Davenport, 1998). ERP implementation is by no means a purely technical system implementation, and will include Business Process Reengineering (BPR). Consultants can perform the role of change facilitator and are involved in very important knowledge transfer. Consulting firms use techniques such as guided learning, formal training and knowledge creation activities to direct clients to the necessary knowledge required for a successful implementation. This guidance saves the client considerable time and effort in knowledge search costs (Gable, 2003).

Without a plan organization would be:

- Vulnerable to unfolding events

- Buffeted by unforeseen factors

- Lack predictability

Traditionally organizations have managed performance by analysing past results. The disadvantage is that. You can’t alter performance after it happens. This is exactly where the strengths of Enterprise Planning lies plan before you perform

ERP is initially synonymous with budgeting. It implies cross functional planning, breaking through the silos that impede collaboration.

The objective of ERP is to bring the information on one holistic view under a common platform.Evolution of ERP

A present day ERP system takes care of the following functional modules.

Characteristics of ERP Systems

- Modular design comprising many distinct business modules such as financial, manufacturing, accounting, distribution, etc.

- Use centralized common database management system (DBMS)

- The modules are integrated and provide seamless data flow among the modules, increasing operational transparency through standard interfaces

- Flexible and offer best business practices

- Require time-consuming tailoring and configuration setups for integrating with the company’s business functions

- Modules work in real time with online and batch processing capabilities

- Internet-enabled

- Financial and business information is often generated automatically by ERP systems based on data previously entered, without further human instructions

- ERP provides business intelligence tools like Decision Support Systems, Executive Information System, Reporting, Data Mining and Easy Warning Systems for enabling people to make better decision and thus improve their business processes

Architecture of ERP System

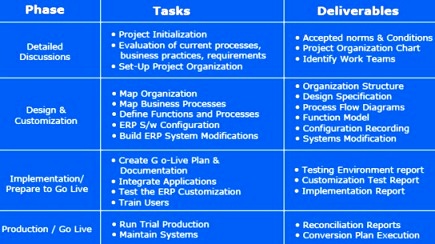

Implementation of ERP Systems

Businesses have a wide scope of applications and processes throughout their functional units, producing ERP software systems that are typically complex and usually impose significant changes on staff work practices. Implementing ERP software is typically too complex for in-house developers, lacking the required skills, so it is desirable and advisable to hire outside consultants who are professionally trained to implement these systems. This is typically the most cost-effective way. There are three types of services that may be employed - Consulting, Customization, and Support. The length of time to implement an ERP system depends on the size of the business, the number of modules, the extent of customization, the scope of the change, and the willingness of the customer to take ownership for the project. ERP systems are modular, so they don't all need be implemented at once. Implementation can be divided into various stages, or phase-ins. The typical project is about 14 months and requires around 150 consultants. A small project (e.g. a company of less than 100 staff) can be planned and delivered within 3–9 months; however, a large, multi-site or multi-country implementation can take years. The length of the implementations is closely tied to the amount of customization desired.

To implement ERP systems, companies often seek the help of an ERP vendor or a third-party consulting company. Consulting firms typically provide three areas of professional services: consulting, customization, and support. The client organization can also employ independent program management, business analysis, change management, and UAT specialists to ensure their business requirements remain a priority during implementation.

Reasons for implementation of ERP

- To support business goals

• Integrated, on-line, secure, self-service processes for business

• Eliminate costly mainframe/fragmented technologies

- Improved Integration of Systems and Processes

- Lower Costs

- Empower Employees

- Enable Partners, Customers and Suppliers

Critical Success Factors for ERP Implementation

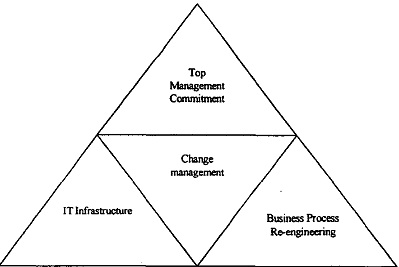

1. Top Management Commitment: Management must be a part of ERP implementation and it has been clearly demonstrated that for IT projects to succeed top management support is critical. However top management in any organization still views the installation of an ERP system as primarily a technological challenge and assigns its responsibility to the IT departments. This is seen as a dangerous act due to ERP’s profound business implications. “Only top management is equipped to act as the mediator between the imperatives of the technology and the imperatives of the business”.

2. Business Process Re-engineering: Implementing an ERP system involves reengineering the existing business processes to the best business process standard. ERP systems are built on the best practices that are followed in the industry and to successfully install ERP, all the processes in a company have to conform to the ERP model.

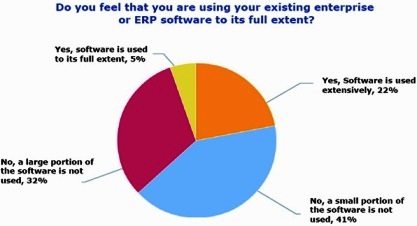

During ERP planning phase, companies also face a question as to whether to implement the ERP software “as is” and adopt the ERP systems built in procedure or customize the product to the specific needs of the company. Research shows that even the best application package can only meet 70% of the organizational needs and thus organizations need to change their processes to confirm to the ERP package, customize the software to suit their needs not be concerned about meeting the balance 30%.Infact this need to reengineer the organization’s business process has been cited as one of ERP’s major benefits. The following survey reinforces the research findings.

3. IT Infrastructure: Adequate hardware and networking infrastructure are required for ERP application. An ERP system relies in its operation on sophisticated information technology infrastructure. In addition to this infrastructure the software configuration has critical influence on the implementation process and outcomes.

4. Change Management: One of the main obstacles facing ERP implementation is resistance to change. About half of ERP projects fail to achieve benefits because managers underestimate the efforts involved in managing change. To successfully implement ERP, the way organizations do business will need to change and the way people do their jobs will need to change too. Thus change management is essential for preparing a company for the introduction of an ERP system and its successful implementation. However, Change management has to be structures within an overall Business process management methodology to achieve its goals.

Five Levers of Change to be addressed

ERP implementation Life Cycle

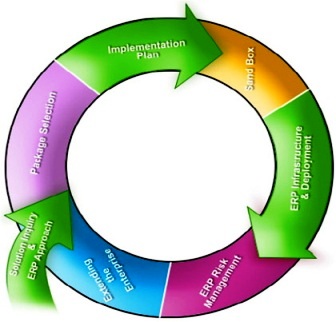

Various Stages, Inquiries and best practices of an ERP implementation cycle are explained below:

Stage 1: Solution Inquiry

Key questions that a business should ask are:

- Are we ready for ERP?

- How will an ERP help our business?

- Have we considered other solution areas beyond ERP?

- Who will lead our implementation effort?

Best Practices

- Identify what benefits the organization needs to get out of an ERP, and focus on these benefits throughout the implementation

- Executive management should endorse the ERP project

- Develop a Mission Statement or Project Charter

- Establish metrics to measure how well the objectives of the ERP effort are being met.

- Designate a Project Champion

- Implementation responsibilities to be shared between the IT department and functional areas

- Build a framework for participation from all quartersStage 2: ERP Approach

Key questions that a business should ask are:

- Do we have the in house resources, skills and experience to implement ERP?

- Should we build effective strategic partnerships?

- Have we considered how the implementation will differentiate our business?

- Have we developed a business case for the ERP implementation project?Best practices

- Determine the number of partners, the scope of the partnerships etc.

- Set up the internal project team

• Steering Committee (Executive level)

• Advisory Committee (One level lower,-Key Directors & major stakeholders)

• Cross Functional Project Team

- Create the business case, justification & ROI scenarios to determine the most feasible

- approach

- Ensure that all gaps between plans & performance are closed outStage 3: Package selection

Key questions that a business should ask are:

- Do the features and functions meet our needs?

- Is the ERP package compatible with our business?

- Should we buy an integrated package from a single vendor or best-of-breed solutions from several vendors?

Best practices

- Develop and document a project scope statement

- Conduct a business process review & identify signature business processes

- Document “as is” flows of current information

- Identify functional gaps

- Document & sign off “to-be” flows of current information

- Customize the RFP to include features that meet your “to-be”flows

- Key factors should be kept in mind while selecting the software

• Functional Capabilities

• Technical Attributes

• Partnership’s Capabilities

• Cost

Stage 4: Implementation Plan

Key questions that a business should ask are:

- How do we get started with the implementation

Methodologies

- The Big Bang

- Modular Implementation

- Process Oriented Implementation

Best Practices

- Procure and install required hardware and package software

- Roll out with preliminary implementation plan that covers

• A Phased Approach

• Segregation of Duties Plan

• Quality Plan

• Security Plan

- Package training for implementation team

- Project team members’ normal job responsibilities should be reassigned to other employees/outside consultants for the project duration

Stage 5: Sandbox

Key questions that a business should ask are:

- What steps do we take to ensure that the implementation is on track?

Best Practices

- Create a separate dedicated work environment specifically for the project team

- Build user acceptance test scripts

- Identify required custom reports

- Implement a system of sign off’s & hand off’s for deliverables and work products

- Ensure complete data migration from the old software system to the new begins early in the implementation process

- Constantly evaluate risks, constraints & assumptions

- Develop training plan for all users

- Develop rollout plan

Stage 6: Design & Deployment

Key questions that a business should ask are:

- How do we ensure that the project team and the end users are in sync?

- How do we ensure that our people are accepting change?

Best Practices

- Roll out training plan for all users in a phased manner

- Conduct user group conferences & prototype sessions to demonstrate the system’s capabilities

- Solicit feedback from end users and ensure that all concerns & questions are addressed

- Encourage end users to network with peers at other institutions undergoing similar implementation initiatives

- Ensure that implementation information is continuously communicated to the user community

- Pilot rollout / evaluation

- Complete live rollout - rollout support

Stage 7: ERP Integration

Key questions that a business should ask are:

- How do we integrate the ERP with our other legacy systems?

Best Practices

- Design interfaces (if required) to integrate existing applications (e.g. CRM, HR) directly with the ERP system

- Ensure adequate documentation exists to support the integration between interfaces

Stage 8: IT Infrastructure

Key questions that a business should ask are:

- Is our IT infrastructure ready for ERP?

Best Practices

- Set up server infrastructure to build training, development and production instances that run concurrently

- Ensure that the infrastructure can handle the load of concurrent transactions from all instances

- Ensure system security policy is in force

Stage 9: Operations

Key questions that a business should ask are:

- How will we recover from a major outage?

Best Practices

- Execute a onsite maintenance SLA with partners

- Implement a Disaster Recovery Plan

- Review Business Impact & Associated Risk

- Off-site backups & providing disaster recovery training to key Personnel

Stage 10: Extending the Enterprise

Consider expanding ERP to other solution areas like

- Supply Chain Management

- Customer Relationship Management

- E-commerce Solutions

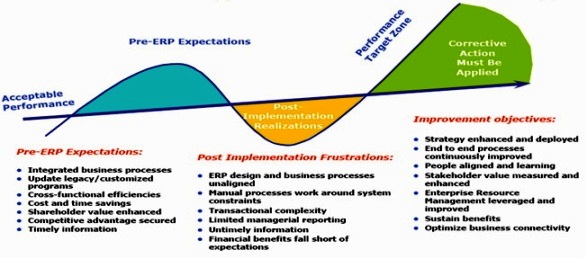

ERP Implementation performance falling short of expectations

Why Do Projects Fail/ Succeed??

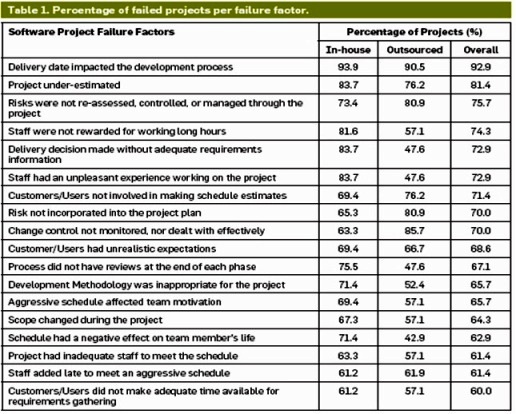

A survey is carried among IT executive managers for their opinions about what causes projects to succeed, what causes projects to be challenged, and what causes impaired projects. Below are the results of this survey (Standish Group,1995).

Project Success Factors and % of Responses

1. User Involvement 15.90%

2. Executive Management Support 13.90%

3. Clear Statement of Requirements 13.00%

4. Proper Planning 9.60%

5. Realistic Expectations 8.20%

6. Smaller Project Milestones 7.70%

7. Competent Staff 7.20%

8. Ownership 5.30%

9. Clear Vision & Objectives 2.90%

10. Hard-Working, Focused Staff 2.40%

11. Other 13.90%

Human resources were not the top factors that determined the project success. Competent staffs ranked number seven and hard-working, focused staff ranked 10. Success is classified as the project is completed on time and budget, with all the features and functions as initially specified.

Project Challenged Factors and % of Responses

1. Lack of User Input 12.80%

2. Incomplete Requirements & Specifications 12.30%

3. Changing Requirements & Specifications 11.80%

4. Lack of Executive Support 7.50%

5. Technology Incompetence 7.00%

6. Lack of Resources 6.40%

7. Unrealistic Expectations 5.90%

8. Unclear Objectives 5.30%

9. Unrealistic Time Frames 4.30%

10. New Technology 3.70%

The human factor was one of the midrange factors for the projects that were challenged. Lack of resources ranked number six. Challenged is classified as the project that completed and operational but is over budget, over time estimate, and has fewer features and functions than originally specified.

Project Impaired Factors and % of Responses

1. Incomplete Requirements 13.10%

2. Lack of User Involvement 12.40%

3. Lack of Resources 10.60%

4. Unrealistic Expectations 9.90%

5. Lack of Executive Support 9.30%

6. Changing Requirements & Specifications 8.70%

7. Lack of Planning 8.10%

8. Didn't Need It Any Longer 7.50%

9. Lack of IT Management 6.20%

10. Technology Illiteracy 4.30%

11. Other 9.90%

The human factor played a significant role in the impaired projects. Lack of resources ranked number three, and technology illiteracy ranked 10. Impaired is classified as the project is canceled at some point during the development cycle.

There seemed to be a direct relationship between project failure and the human factor contributions. The larger the failure, the more the human factor contributed to that failure. This is more evidence that most software development projects fail because of failures within the team running them.

This study concluded that the success rate was only 16%, challenged projects accounted for 53%, and impaired for 31%. (Standish, 1998). Lack of resources seems to be a major contributor in why teams fail. Without the necessary staff, it is very difficult to manage the project team effectively.

With a large percentage of the projects being challenged or impaired (84%), the human factor should not and cannot be ignored by the IT industry as a problem that needs to be addressed. Otherwise, the current problems will continue to repeat themselves in this fast-growing industry.

Reasons for Failure

Projects in general fail for various reasons. Several factors contribute to failed IT software development projects include:

- lack of senior management commitment

- lack of user involvement

- lack of user requirements specifications

- poor project planning

- project team problems

The above factors also contribute to team failure in one aspect or another. However, some of the more specific reasons for the failure of teams include:

- improper use of application development tools

- inappropriate allocation of team members

- lack of appropriate application development tools

- lack of or insufficient communication between team members

- lack of or insufficient communication with users

- lack of use of structured method (i.e. System Development Life Cycle method)

- shortage of team members

- uncommitted team members

- unskilled team members

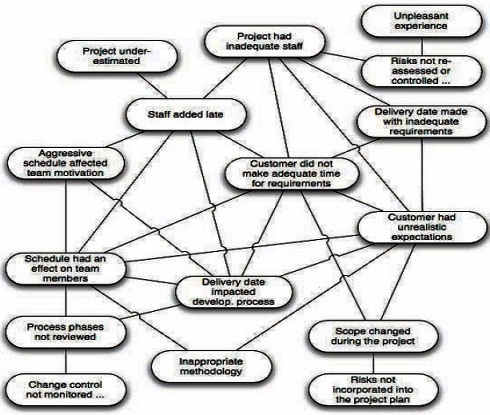

Critical Failure Factors for ERP Implementation

1. ERP system misfit

2. High turnover rate of project team members

3. Over-reliance on heavy customization

4. Poor consultant effectiveness

5. Poor IT infrastructure

6. Poor knowledge transfer

7. Poor project management effectiveness

8. Poor quality of Business Process Re-engineering (BPR)

9. Poor quality of testing

10. Poor top management support

11. Too tight project schedule

12. Unclear concept of the nature and use of ERP system from the users’ perspective

13. Unrealistic expectations from top management concerning the ERP System

14. Users’ resistance to change

Relationships between most important software failures

ERP Implementation at Hewlett Packard – Challenges and Failures

Introduction

HP is started in 1938 by 2 Stanford Engineers BILL HEWLETT and DAVID PACKARD as an electronic instrument company. Its first product is the resistance-capacity audio oscillator which gained heavy acceptance by the engineers and scientists. HP’s growth was aided by heavy purchases by the US government during the WWII.

Historical Developments

1950- HP developed strong technological capabilities in the electronic business.

1951- HP invented the high speed frequency counter.

1957- HP came out with the 1st public issue.

1961- HP ventured into the medical equipment industry by acquiring Sanborn Company.

1966- Established HP Laboratories and also designed its first computer.

1974- Launched 1stminicomputer on 4K DRAM

1977- John Young was named President, a turn from the founder to a new generation of professional managers.

1980- HP offered full range of computers from Desktop to powerful minicomputers.

1980- Developed Inkjet & Laser printers.

1981- Introduced the 1st Personal Computer.

1982- Introduced Electronic Mail System.

1982- Introduced HP9000 with a 32-bit super chip.

1989- Purchased Apollo Computers and became the leader in Workstations.

1997- Acquired Electronic Transaction Co. VERIFONE for $1.2bn

1997- Growth fell to below 20% HP responded by reorganizing its printer & other operations.

1999- Spun off its test-&-measurement division into an $8bn separate business.

2001- Second largest computer manufacturer.

HP's operations are organized into seven business segments:- Enterprise Storage and Servers ("ESS"),

- HP ProCurve,

- HP Enterprise Services ("HPES"),

- HP Software & Solutions,

- Personal Systems Group ("PSG"),

- Imaging and Printing Group ("IPG"),

- HP Financial Services ("HPFS"), and

- Corporate Investments.

The three business segments ESS, HPS and HP Software & Solutions are structured beneath the broader Enterprise Business (EB) Group in order to capitalize on up-selling and cross-selling opportunities, and give a solution sale approach across the HP enterprise offerings. HP was ranked 11th as per the Fortune 500 ranking in 2004

HP and SAP

HP had close partnership with SAP since 1989 when SAP began developing SAP R/3 product. Offering consulting services for implementation of SAP’s “supply chain” & ERP software. First SAP R/3 was deployed on an HP 9000 Enterprise server in 1992 at Wuerth .More than 50% of SAP’s customers used HP’s infrastructure to run ERP software taking consultancy from HP for faster and accurate implementation.

HP announced that its revenues have gone down by 5% to $3.4bn for the 3rd quarter ended July 2004. The reason proposed was due to the problem faced during the migration to the centralized ERP system. The total financial impact due to the failure was $160mn.

Questions were raised on failure of HP implementing ERP, as it was a consultant for SAP ERP implementation. HP’s responsibility as a consultant was to prevent the execution problems faced by the implementing Co. on which it itself failed. While conducting an internal serve, HP revealed that there has been execution problem and not the fault of SAP. Technical glitches were small but contingencies planning weren’t addressed appropriately.

HP had a highly decentralized org. structure & every business operated independently. HP redesigned its business strategy to venture into high volume low priced electronic market. Therefore HP planned to phase out its numerous legacy systems and replace it with SAP R/3.

Objectives of implementing SAP R/3 are:

1) Shorter lead & delivery time

2) Cost Saving

3) Global Distribution System

In 1993, HP’s BCMO unit began with the implementation with several modules like- MM, PP, FI, CO. FI & CO modules were implemented on global basis & SD was implemented as part of pilot project. By 1998, major migration to SAP R/3 was completed. The implementation of SAP Sales Configuration Engine enabled E-commerce for direct consumer selling and HP kept on upgrading the version as the needs changed.

Implementation of MySAP

By 2000, HP was keen in making the web-based activities simpler to capture the direct to customer market and had over 20 SAP R/3 implementations representing FI, PP, MM, SD, CO, BW, WM & APO. HP used different version of SAP & had multiple SAP GUIs with around 10,000 users. As HP was using SAP R/3, it considered using My SAP for its Internet Enabled Technology Businesses to be a better fit.

Benefits of My SAP:

- Reduce huge cost incurred on IT support

- All programs will run on single browser

- Eliminate need to create custom SAP interface

- Greater speed in implementation

- It had the option of query which would make it easier to use.

Further, HP wanted to link its employees, customers & partners. HP faced problem in fulfilling orders when any order involved various items from more than 1 product line. HP wanted to ship the products faster as the demand placed on HP’s supply chain data workflow increased tremendously. The main aim was to cut cost, increase transparency & equip itself to the changing business models. HP decided to implement the APO module, the central element of SCM.

SAP’s APO & SCM software were first implemented in Europe imaging & printing division. It helped to forecast & enabled integration of data in a single system. It was introduced in just 5 months’ time. After its merger with Compaq in May 2002, it started repairing the SC of all businesses to create 5 standard SC supported by standard technology platform. It introduced the “ADAPTIVE SUPPLY CHAIN”. It also implemented PLM (Product Life cycle Management) module to integrate the product lines of the 2 merged Companies.

ERP Migration Failure

In Dec 2003 Gilles Bouchard, the CIO & EVP created a model to merge the Business and IT group at regional & country level. This operation along with the ISS was completed by on May 2004 & that led to increased interdependencies between groups in the company. This was 35th Migration and was a part of the Business Process Architecture. HP wanted to reduce the 35 ERP systems implemented worldwide to four along with reduction in application from 3500 to 1500.

HP wanted to implement a single Order Management System & successfully reduced the no. to 7 but still wanted further efficiency & flexibility with the implementation of SAP FOM platform. With the FOM, HP wanted to unite the SAP of Compaq with itself. It involved migration from separate HP & Compaq legacy SAP R/3 to a new Broad-Based SAP ERP system & this involved more than 70 supply chain & up gradation to SAP R/3 Version-4.6C.

HP took over an empty factory at Omaha to frame the contingency plan to include both the technical and business aspects so as to provide buffer stock for customized order. But as soon as the project went live in June 204, Migration problems began surfacing. About 20% of the orders failed to move from the legacy system to the new one due to programming errors. HP was able to fix this within a month but orders began to backlog.

Causes Identified for Failure

The following are the causes of the migration failure:

1. Project Team Constitution

2. Data Integration Problem

3. Demand Forecasting Problems

4. Poor Planning & Improper Testing

5. Inadequate Implementation Support/Training

Analysts commented that the Co.’s culture did not support the much active involvement of employees also Co. ignored valuable suggestion from employees. Co. staff had warned HP but it was not possible for it to continue with the tradition system and also suggested for a back-up system but Co. turned deaf ears over that. Many Vice-President had joined the rival Co. and also many employees had a fear of been laid off.

HP had traditionally been a very systematic, risk averse & slow as compared to Compaq’s culture of being very aggressive & risk loving. HP once again failed in 2005 while implementing “GENESIS” while competing “DELL”. There was an expert group who had the entire know-how to implement ERP but it was dominated by the IT management.

Learning from ERP Implementation Failure at HP

- Implementation failure can impact overall business performance.

- There is no standard approach to implement ERP, many times it involves a business change in many departments. Therefore a detailed mapping is essential otherwise it might miss out the objectives.

- The success of implementation depends upon the planning, which considers the business process along with the technical aspects.

- To implement ERP, the business processes must be improved & corrected but HP failed in this.

- “The potential benefits to the supply chain are much bigger than the IT costs but the potential risk to the supply chain is also much bigger”.

- The success of ERP implementation depends upon the ability to align IT along with the business management objectives, Program Management Skills and a well defined process.

- Impossible for HP to envision the entire configuration for Customized orders.

- There should be a manual back-up as a contingency plan.

- There should be no cross-functional barriers and should create effective processes and teams to integrate the entire business at all levels.

- Encourage employees.References

1. Gable, g. “Large Package Software: A Neglected Technology?”, Journal of Global Information Management, Vol 6,No.3,Summer 1998.

2. Barnes, M. “Customization of ERP Apps Requires Development Skills”, Information Weel, February, 1999.

3. Oliver, D. and Romm, C.” enterprise Resource planning systems: An outline Model of Adoption”; I proceeding of GITM World Conference, Memphis, TN USA, 11-13 June 2000.

4. Bingi, P.; Sharma, M.K; and Godla, J.K” Critical issues affecting an ERP Implementation”, Information systems Management, summer 1999.

5. Davenport, T. “Putting the enterprise into the enterprise system”, Harvard Business review, Vol.76, no.4, July-August 1998.

6. Gupta, A.” Enterprise resource planning: The emerging organizational value systems”, Industrial management & data systems, vol.100,Issue.3, 2000

7. . A Guide to the Project Management Body of Knowledge. Upper Darby: Project Management Institute.

8. McConnell, Steve (1998). Software Project Survival Guide. Redmond, Washington: Microsoft Press.

9. McConnell, Steve (September 1996). Classic Mistakes. [On-Line]. Available: http://www.construx.com/stevemcc

10. The Standish Group. (1998). Chaos. [On-Line]. Available: http://www.standishgroup.com/chaos.html

11. Yourdon, Ed and Becker, Paul (April 1997). Death March: The Complete Software Developer’s Guide to Surviving ‘Mission Impossible’ Projects. Prentice Hall Computer Books.

12. Yourdon, Ed (April 1997). Making Death March Projects Pay Off. [On-Line]. Available: http://www.datamation.com/PlugIn/issues/1997/april/04proj.html

13. Critical Failure Factors in ERP Implementation- Ada Wong , Harry Scarbrough, Patrick, Y.K. Chau, Robert Davidson.